What is a mockup? Generally it is a quickly built prototype.

• a mockup gives a good feel for the real space

• a mockup helps focus on usability and function rather than materials and small details

• a mockup allows you to interactively problem solve

• encourages experimenting, the materials are easy to work with and inexpensive

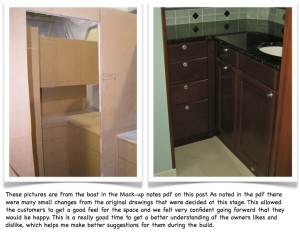

Mockups are commonly used by designers and builders to get real world feedback on a design or space. Yes there are drawings, but those don’t give the full-scale walk through the space experience. And in reality most people can’t visualize from a 1/2 inch to the foot scale drawing. In a yacht interior, often we are balancing taking an inch here and giving an inch there just to make everything work. Sometimes this is due to a constraint such as, the size of an appliance or equipment access and sometimes it is more related to what works for the specific customer. Is there room to walk through reasonably? Does that cabinet block my view? Will I hit my head going down the stairs? It really is much better to discover any problems before the actual building begins. Generally they are not that hard to fix, in fact you can work them out in the mockup quickly, then make sure that the changes are documented. This information does need to be incorporated into the build drawings and notes or it will do no good. This pdf, Mock-up notes , is from the documentation of a Northwest Trawlers 50.

After the walk through and adjusting the basic spaces I like to move on to usability and function. Standing in the galley I’ll go through the steps of getting a pan out, opening the refrigerator for the eggs, back to the stove , where is the spatula. Are the steps convenient, is the layout going make the galley a pleasant work space? Would I like to cook in this space? One of the most common mistakes I see in the galley is that the dishwasher is placed too close to the sink, making it nearly impossible to stand at the sink and load the dishwasher, even though it looked reasonable on the scale drawings. I go through the boat area by area and act out different activities. Is there room to get dressed in the guest stateroom? Will I hit my elbow on the bulkhead when I stand at the head sink and shave? Do all of the door swings seem right? Go through everyday motions and see what works and more importantly, what doesn’t.

Hopefully you have found most of the problems in the previous exercises, lets work on fixing them. Going back to the galley, we need to rearrange things a bit so we can use the dishwasher more easily. What can we move? If it is a dishwasher drawer then it can go below the sink and work pretty well. Play with all of the components until it looks like it will reasonably well. A door swing that needs to be changed will potentially impact wiring, you do not want the light switches behind the door when it opens. Is there room for the switches on the other side of the door? Sometimes fixing one problem cascades right into another problem. It is much better to discover these things on the mockup rather than on the real build.

Now that we have adjusted, pushed, pulled and tweaked things into order we can do some detailing and experimenting with the space. I like to go through and draw more details onto the surfaces, drawer faces, cabinet doors, appliance faces, sinks etc. Also if you have samples of hardware, such as drawer pulls, you can place them onto a few of the fronts and see which look the best in the space. Drawing in details such as the HVAC grills, switches, sconce lights all help give you a better feeling of the space. You can try variations in an area quickly and inexpensively while we are still in cardboard and sticks rather than lumber and veneer.

After going though all of that you should have a much better understanding of how the interior will feel. The arrangement should be locked down now, though to be honest there will likely be small adjustments all the way through the build. This new found understanding of the interior should help with final selection of details like wood species and grain patterns, architectural details, hardware and long list of other choices and decisions that will need to be made as the project progresses.

I do feel that this is an important step that almost always helps us build a better interior, build more efficiently, avoid going backward during the build and have a happier customer in the end.

Dan

4 Comments

Trackbacks/Pingbacks

- 4 Preliminary Steps When Starting a Yacht Interior Design - […] Interior mock-ups link to cardboard and sticks […]

Well, this skill surely helped to make the Salish Sea IS48 an incredibly beautiful finished product, with amazing use of space and storage.. thank you Dan

Dan, thank you for the comment. The overall fit and finish of the Salish Sea is very good, I feel fortunate to have been involved in that project.

I feel very strongly about mocking up projects, or at least parts of them. I am presently working on a 110′ yacht/fisher. We mocked up quite a bit of that interior, this allowed the customer to make several changes that were not obvious when looking at the drawings.

Dan

Dan,

Awesome site. I recently bought a 36′ sailboat which I will be reducing down to basically a bare hull and starting over. How did you learn to use Sketchup for Yacht design? Where do you do your mockups?

Rick

Rick, thanks for taking time to visit my site, I’m glad that you have found it interesting.

Starting with a bare hull puts you years ahead of starting from scratch. 36 foot is a big project, but properly planned out it is very doable. I hope you will post pictures as the project goes forward.

I started using sketchup to draw details and cabinets for large yachts several years ago and have just kept working on my skills since then. I enjoy using the program and often design a cabinet or detail just for fun. As far as learning to use it, there are many great resources on line. Youtube has great tutorials as does Fine Woodworking at http://www.finewoodworking.com/blog/design-click-build. Sketchup has about the most reasonable learning curve I’ve seen for a 3d modeling program.

If there is a hull to work in, I would prefer to do the mockup inside it, it’s quicker and easier. For the mockup of the IS48 the molds were still being cut so we were months from having a hull, we framed up decks in the shop then did a complete cardboard interior to prove out the design.

I’m busy on a big project right now, but I will try to find the time to make up a post on the basic techniques of doing a mockup. Over the years I’ve learned a few things that make it go pretty quickly and they look nice.

Dan