It’s launch day, and after months or maybe years of hard work by many people, the project is nearly done. The crew has cleaned every nook and cranny, the art work is in place and there are only a handful of items that must be completed after sea trials. If you asked them, most of the build crew would tell you that this is the best one they have built. We all hope that each is a little better than the last one. In short the new yacht looks magnificent. But really most new yachts look very nice on launch day, what I always wonder when I am looking through one is how will this look after five or ten years of use? Boats move and twist, wood work gets bumped and dinged, it all takes a toll. That toll can be minimized and over time the look will be more like that of a cherished antique. Aside from how the interior is treated by people on board, there are many factors that affect how it holds up, the following paragraphs cover some of them.

Initial design considerations

This one starts with the look and feel concepts. How the design elements interact with one another is very important, not just for the overall look, but this will affect how well it all holds up. Some core issues are, solid wood is tougher than veneer. Denser woods are generally harder to damage than lighter woods. Wood moves (expands and contracts) with changing humidity. Solid wood moves at a different rate than plywood. So what do these items have too do with the look and feel ? These issues need to be designed around, and , unfortunately not all yacht builders or even many interior designers really seem to understand this very well.

Once the initial parameters, general style, level of detail, budget etc. are established I like to work out some of the key joinery details. Typically I start with cabinet corner posts, bulkhead corner posts, sea rails, and door jambs and casings. This establishes the general direction that the rest of the details will follow.

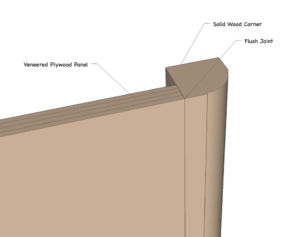

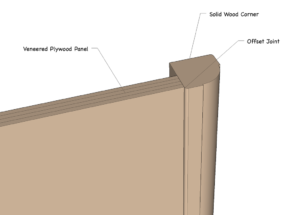

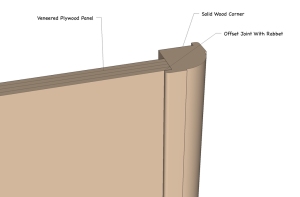

The cabinet and bulkhead corner posts will be similar but typically the ones on the cabinets will be smaller. The three most common corner post to panel joints are: Flush, Offset and Rabbeted Offset (please see the images below).

Flush: The Flush joint is difficult and generally more time consuming to do correctly, the adjoining faces of the post and panel need to be nearly perfect to look seamless. They need to be level, if when assembled the solid wood is a fraction of an inch to high it is not hard to level it out, but not so if the veneer is too high. Veneer thickness ranges at best from 1/32″ ( .03″) to about 1/100″ (.01) that leaves very little to work with. I usually opt for custom laid up veneers in the thicker range. The joint, if not well executed, is very likely, over time, to show cracking in the finish, especially if the finish is applied thicker than the manufacture recommendation. For conversion varnish, a common finish on quality yacht interiors, thats about .004″. For comparison, copier paper is about .004″.

Offset: The Offset joint is a bit easier to build and it masks minor imperfections in the joint much better. The wood will still move around a bit but this joint will show it less than the flush joint. The solid wood protects the relatively fragile veneer edge.

Rabbeted Offset: This is generally my first choice. It has all of the good attributes of the Offset joint but is easier to get a good quality, long lasting, tight joint with this type of joinery. The rabbet also forces the offset depth to be consistent, it is machined into the corner post. For another example look here.

With the above examples we are looking only at how the corner joins the panel, not the look of the panel, the style or profile of the corner post, or any of the many variations that are possible. This is just the basics.

Dan